BUILDING TODAY & TOMORROW WITH GREEN IN MIND

Hyundai L&C (Living & Culture), part of Hyundai Department Store Group, is a member of the U.S. Green Building Council (USGBC), the promulgator of Leader ship in Energy and Environmental Design™ (LEED®) green building guidelines. W e are committed to being a pro-environment company creating eco-friendly products for the marketplace. We focus our product research and development, manufacturing approach and recycling efforts toward demonstrating how we value the environment and wish t o protect its future for generations to come.

CLICK HERE TO DOWNLOAD OUR DESIGN AND LEED DOCUMENTATION

REDUCE, REUSE & RECYCLE

Most often referred to as the “three R’s”, the phrase “Reduce, Reuse, Recycle” is a simple formula that encourages people, businesses, and municipalities t o utilize goods that are already manufactured rather than continue to use only limited raw materials to produce replacement goods. Hyundai L&C is committed to implementing this simple formula at all North American locations to achieve the following goals:

- Prevent pollution and promote reuse and recycling.

- Reduce priority and toxic chemicals in products and waste.

- Conserve energy and materials.

From recycling 100% of the water used in the production process, installing an air purification system to remove pollutants from the air to a system that collects all dust within the plant, we strive to ensure a healthy workplace along with an eco-conscious approach in product development, waste management and conservation efforts.

SUSTAINABILITY

Hyundai L&C USA is committed to being a pro-environment company creating eco-friendly products for the marketplace. We focus our product research and development, manufacturing approach and recycling efforts toward demonstrating how we value the environment and wish to protect its future for generations to come.

From recycling 100% of the water used in the production process, installing an air purification system to remove pollutants from the air to a system that collects all dust within the plant, we strive to ensure a healthy workplace along with an eco-conscious approach in product development, waste management and conservation efforts.

Specifying Hyundai L&C USA products in green building projects can also contribute to LEED certification points. All of the surfaces are low-VOC in accordance with GREENGUARD’s Indoor Air Quality standards and clean easily with no need for chemical detergents.

NORTH AMERICAN FACILITY

In keeping with Hyundai L&C USA ongoing commitment to environmentally friendly production, the 19,974 sq. m.state-of-the-art facility in Canada utilizes the most advanced, environmentally responsible manufacturing process. Located in London, Ontario, the facility solidifies Hyundai L&C USA's presence in North America as one of the leading producers of fine quartz surfaces – via its HanStone Quartz product line.

ENERGY

One of the most effective ways for us to contribute to the environment is through the conservation of energy. Our building was designed with a very sophisticated HVAC system with minimum air exchange required. And our hot oil-based heating system is a very efficient way to generate heat. As a best practice, we are continually reevaluating and reengineering our operating procedures, to reduce our energy consumption.

WATER

We understand the importance of water conservation and installed a water recycling system as an integral part of the building design and manufacturing process. Our North American plant recycles and reuses 100% of wastewater generated during manufacturing.

SOLID WASTE

Our goal is to reuse, renew or recycle as much of our own manufacturing waste as possible. At our manufacturing plant in Canada we have been able to work with local companies to utilize our byproducts and have challenged our team to reuse our waste and recycle material that cannot be reused.

Example: Our slab scraps are recycled with a local landscape firm. And the rubber molds for the 4x8 slabs are recycled with a local company able to breakdown the rubber and reuse it for weeding and gardening products.

LEED POINTS AVAILABLE USING HANSTONE:

MR Credit 3 Materials Reuse: +

To reuse building materials and products to reduce demand for virgin materials and reduce waste, thereby lessening impacts associated with the extraction and processing of virgin resources.

Use salvaged, refurbished or reused materials, the sum of which constitutes at least 5% or 10%, based on cost, of the total value of materials on the project. The minimum percentage materials reused for each point threshold is as follows:

All of the HanStone products can be reused.

Intent:

Requirements:

Qualifying Products:

MR Credit 4 Materials Reuse: +

To increase demand for building products that incorporate recycled content material, thereby reducing impacts resulting from extraction and processing of virgin materials.

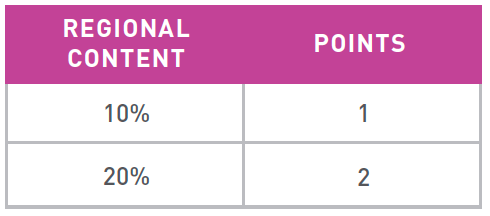

Use materials with recycled content such that the sum of post-consumer recycled content plus ½ of the pre-consumer content constitutes at least 10% or 20%, based on cost, of the total value of the materials in the project. The minimum percentage materials recycled for each point threshold as follows:

Specchio White: Minimum 24% Pr e-consumer recycled mirror content.

Intent:

Requirements:

Qualifying Products:

To increase demand for building materials and products that are extracted and manufactured within the region, thereby supporting the use of indigenous resources and reducing the environmental impacts resulting from transportation.

Use building materials or products that have been extracted, harvested or recovered, as well as manufactured, within 500 miles of the project site for a minimum of 10% or 20%, based on cost, of the total materials value. If only a fraction of a product or material is extracted, harvested, or recovered and manufactured locally, then only that percentage (by weight) must contribute to the regional value. The minimum percentage regional materials for each point threshold is as follows:

All Canada HanStone Products, if job site is within 500 miles of zipcode N6M OC5. Fabrication can be considered “final” place of assembly, therefore if the fabrication is located within 500 miles, then all colors are qualifying.

MR Credit 5 Regional Materials: +

Intent:

Requirements:

Qualifying Products:

IQ Credit 4.1 Low-Emitting Materials-Adhesives & Sealants: +

To reduce the quantity of indoor air contaminants that are odorous, irritating and/or harmful to the comfort and wellbeing of installers and occupants.

All adhesives and sealants used on the interior of the building (i.e. - inside of the weatherproofing system and applied on-site) must comply with the following requirements as applicable to the project’s scope: Adhesives, Sealants and Sealant Primers must comply with South Coast Air Quality Management District (SCAQMD) Rule #1168.

All HanStone materials can qualify if the VOC content of adhesives is less than the current limit specified in SC AQMD Rule #1168.

Intent:

Requirements:

Qualifying Products:

ID Credit 1 Innovation in Design: +

To provide design teams and projects the opportunity to achieve exceptional performance above the requirements set by the LEED Green Building rating System and/or innovative performance in Green Building categories not specifically addressed by the LEED Green Building Rating System.

Path 1. Innovation in Design

Path 2. Exemplary Performance

All HanStone products are both GREENGUARD certified for Children & Schools as well as indoor air quality and therefore may be able to contribute to this credit.

Intent:

Requirements:

Requirements:

Qualifying Products: